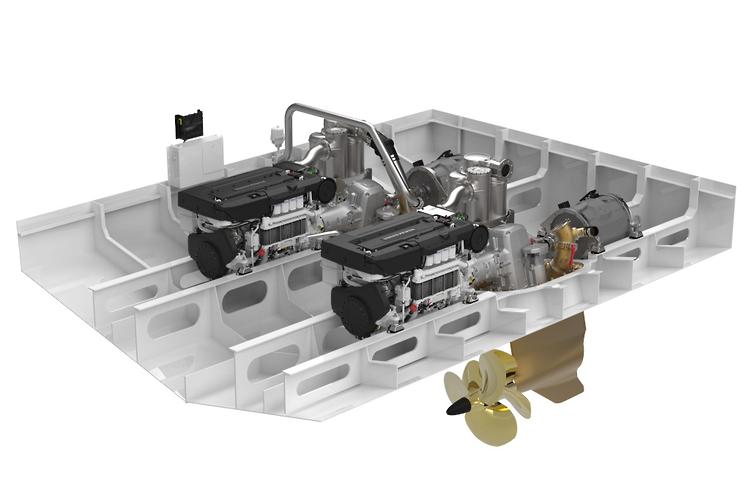

D17 facilitates installation, transportation, and servicing with its lightweight construction and compact design. This feature of its design also contributes to the quiet and low-vibration operation of the motor, offering users both ease of use and comfort.

Designed with sensitivity to alternative and renewable energy sources, the D17 can run on environmentally friendly fuels such as hydrotreated vegetable oil (HVO). This compatibility helps users reduce their carbon emissions while supporting their sustainable energy goals.

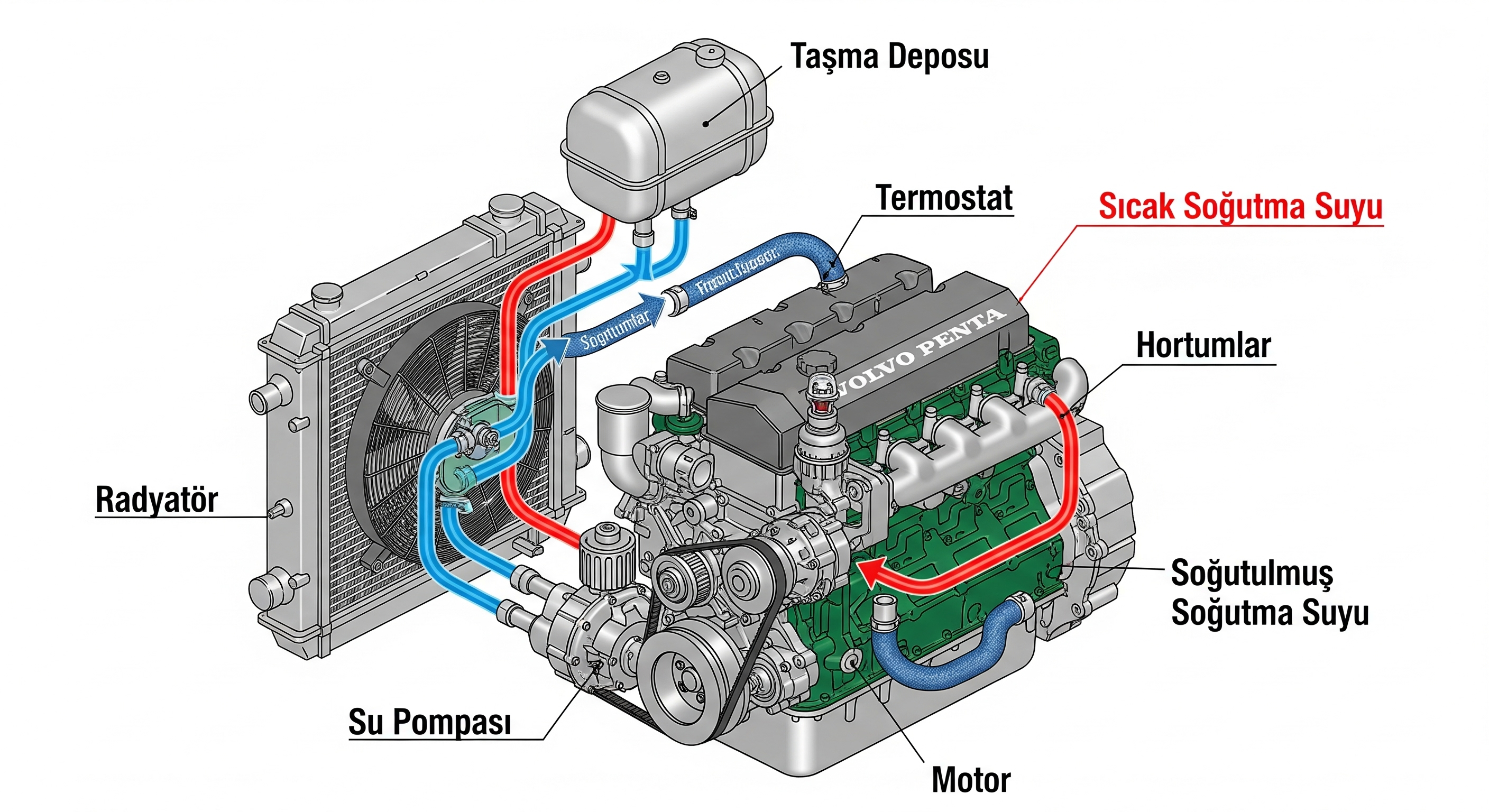

The D17's advanced cooling package adapts to various installations and includes viscous fan and air filter options. This cooling system maximizes engine performance while further reducing fuel consumption and noise emissions.

The 17-liter D17 engine is equipped with heavy-duty steel pistons and two-stage turbochargers. Offering standby power up to 881 kVA and prime power capacity up to 758 kVA, it provides uninterrupted power across a wide range of applications. Its power density makes the D17 a powerful player in industrial generator sets.

Designed for energy transition, the D17 offers users the advantage of achieving low emission values by running on renewable fuels. Volvo Penta's forward-looking approach supports industrial customers in reducing their carbon footprint.

The D17's 1,000-hour service interval and low heat output reduce maintenance and operating costs. Parts compatibility and serviceability also have a positive impact on TCO (total cost of ownership), providing efficiency and cost advantages throughout the engine's operating life.

The D17 motor is designed in accordance with the ISO8528 G3 load acceptance standard, which means it can respond quickly to power outages and meet energy demands. This feature ensures that industrial processes can continue without interruption.

The environmentally friendly D17 engine complies with UNECE REG 96 Stage 2 emission standards. This minimizes the environmental impact of industrial operations and ensures compliance with strict environmental regulations.

With its US EPA Tier 2 Stationary Emergency certification, the D17 can be used as a reliable emergency power source even in areas with strict regulations. Its compliance with certification standards is an indication of the engine's high reliability.

Volvo Penta engineers have developed a larger diameter engine for the D17. This feature provides a larger displacement compared to the D16, enabling a 10% increase in power capacity at 1800 rpm.

Businesses using the D17 engine enjoy a safer user experience with the warranty options offered by Volvo Penta. Global warranty options help ensure that industrial operations can be carried out safely in different geographical regions.

The D17 motor is suitable for a wide range of applications thanks to its dual speed (1500/1800 rpm) design. This speed option provides continuous performance in applications that require high power.

Volvo Penta simplifies installation and maintenance processes by offering all engine components under a single solution. Single-source support provides users with reliable and fast service at every stage.

Thanks to Volvo Penta's extensive global dealer network, customers receive comprehensive support throughout the life of their engines. After-sales support ensures the performance and reliability of the D17 engine.

The D17 is built on the foundations of its predecessor, the D16. This means that existing structures do not need to be modified for new engine installations, allowing users to easily integrate them into their existing systems.

By partnering with Volvo Penta, you get more than just an engine—you get a partnership that extends from the design stage to after-sales service. The D17 engine and Volvo Penta's strong support enable businesses to achieve long-term success.

Our recommendation for the Volvo Penta D17 model

When it comes to engine maintenance, basic maintenance procedures such as regular oil changes and filter cleaning extend the life of the engine and keep its performance at maximum levels. Users should remember that they must immediately consult an expert if they notice any abnormalities in the engine. Obtaining expert technical support for maintenance procedures will increase the efficiency of the engine and minimize operational problems.

Potential buyers considering using the D17 engine should take into account the engine's operating conditions and requirements. The engine's load capacity must be suitable for your energy requirements; this is critical in terms of both performance and fuel efficiency. In addition, it is advisable to seek assistance from a team of experts for the installation and setup of the engine in order to avoid problems and achieve the best performance.